EVA / Vetttõkestav membraan

| Laoühik: | |

| EAN: | |

| Bränd: | Albau |

| Sobilik tootele: | Cavity wall construction |

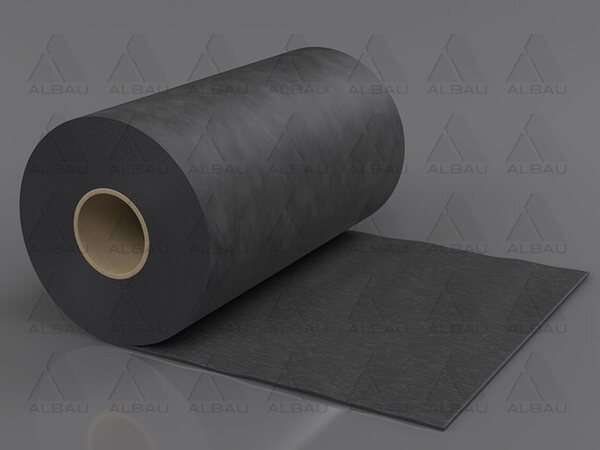

| Materjal: | EVA (ethylene vinyl acetate terpolymer) |

| Rulli pikkus: | 25 m |

| Paksus: | 1,2 mm |

| Root resistance: | acc. to DIN 4062 |

| Temperatuuriline vastupidavus: | -50°C kuni +80°C |

| Värvus: | Anthracite / Grey |

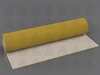

Ethylene vinyl acetate terpolymer (EVA) triple-layer, double-sided non-woven fabric waterproofing membrane for cavity wall construction

Advantages:

- Triple-layer, 1,2 mm thick DIN-compliant and bitumen-compatible damp proof course – elastic and watertight. It meets the requirements of DIN EN 14909, DIN V 20.000-202 and DIN 18533

- The double-sided non-woven fabric enables an excellent connection to the masonry mortar, thereby ensuring high shear strength in the masonry

- The membrane boasts extreme tear strength – longitudinal > 600 N / 5 cm to transverse > 450 N / 5 cm.

- only half as heavy at the same thickness as other commercially available 1,2 mm PVC damp proof courses

- Resistant to rising moisture and rot-proof, securely protecting the masonry from the ground up

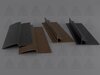

- Used as a horizontal barrier layer installed in the lowest horizontal joint of the masonry between two mortar layers and can also be used as an L- or Z-barrier in a cavity wall. It can also be used in the area of wall openings, such as window openings, lintels or balustrades

- Easy and efficient to install and is easy to cut from the 25 m long roll

- UV-stabilised and retains its flexibility at all temperatures

- Can be glued with elastic glue for waterproofing membrane (ALB-GLUE-WM/310)

Installation:

- The waterproofing EVA membrane is laid in one layer.

- The surface must be levelled out using Group 2 or 3 mortar acc. to DIN 1053 in order to obtain an even surface

- Then fit the membrane into the horizontal joint between two mortar layers on the base slab

- At the joints, a sufficient overlap of 20 cm must be ensured

- The width of the damp proof course must be selected so that no moisture bridges can form to the side of the bricked-up wall

- As an L-barrier in a cavity wall, the membrane is glued to the rising masonry with elastic glue

- As a Z-barrier in a cavity wall, the membrane is fit into the shell masonry, then later inserted into the facing shell