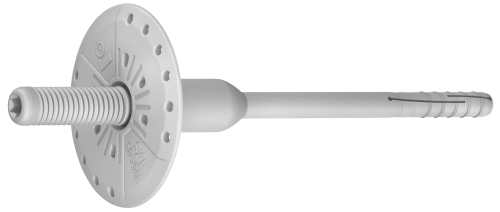

R-TFIX-8S / Screw-in facade fixing

| Артикул: | |

| EAN: | |

| Бренд: | Rawlplug |

| Для: | ETICS, polystyrene (EPS), mineral wool (MW), polyurethane (PU) boards |

| Тип: | Screw-in |

| Точечная теплопроводность, W/K: | 0,001-0,002 |

| Минимальное расстояние между точками крепления, мм: | 100 |

| Минимальное расстояние от края основания, мм: | 100 |

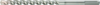

| Диаметр дюбеля, мм: | 8 |

| Диаметр отверстия в основании, мм: | 8 |

| Диаметр тарелки, мм: | 60 |

| Жёсткость манжеты, кН/мм: | 0,6 |

| Прочность манжеты, кН: | 2,04 |

| Разрешительные документы: | ETA 17/0161; UKTA-22/6348 |

Versatile Rawlplug screw-in facade fixing R-TFIX-8S with high performance in all base materials, recommended for ETICS

Features and benefits

- Quick and easy installation in all substrates (categories A,B,C,D,E)

- Unique sleeve compression zone for precision installations

- The long plastic overmoulding on the R-TFIX-8S screw minimises thermal bridging (value 0,001-0,002W/K), contributing to energy-saving benefits

- Plate stiffness (value 0.6 kN/mm) ensures smooth elevation surface and stable insulation system

- Unique design allows for high load-bearing capacities. This reduces the quantity of fixings required per square metre of insulation

- The shortest embedment depth at the maximum strength parameters

- Pre-assembled screw saves time and labour

Applications

- External Thermal Insulation Composite Systems (ETICS)

- Polystyrene (EPS) boards

- Mineral wool (MW) boards

- Polyurethane (PU) boards

- Cork boards

- Light wood wool building boards

Installation guide

- Drill a hole of required diameter and depth

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in Aerated Concrete Block

- Clean drilled hole 3 times

- Insert driver bit into recess in head moulding of R-TFIX-8S screw

- Insert the fixing into the drilled hole

- After inserting the fixing in the hole, the plate should be pressed against the thermal insulation surface

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block

- Apply steady axial pressure, ensuring the disc of the setting tool is kept perpendicular to the fixing axis

- Steadily drive in the screw with high revs until fixing is secure (when disc touches insulation surface)