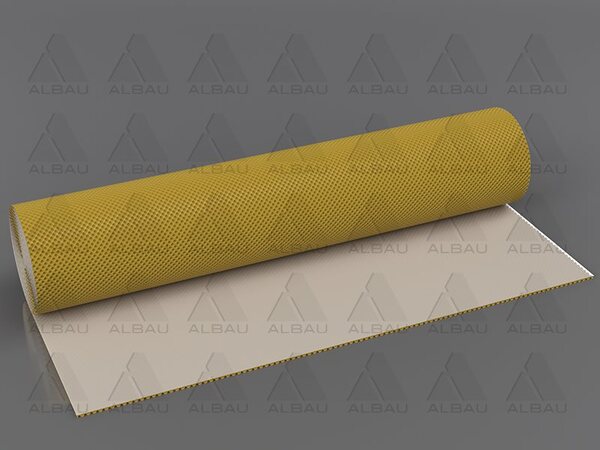

11-500 / Drainage geomembrane

| SKU: | |

| EAN: | |

| Brand: | Albau |

| Material: | HDPE (high-density polyethylene) |

| Geotextile: | Polypropylene |

| Roll length: | 20 m |

| Dimple height, mm: | 11 |

| Dimples/m²: | 4000 |

| Compressive strength, kN/m²: | 500 |

| Chemical properties: | Chemical resistant |

| Physiological properties: | Safe for drinking water |

| Temperature resistance: | -30°C to +80°C |

| Color: | Yellow |

The double-layer dimpled membrane is the new champion among the protection and drainage systems and the best solution for horizontal and vertical surface drainage on all pressure-resistant substrates

Advantages:

- The membrane consists of an innovative dimpled sheet with specially reinforced and trowalized dimples for extra high drainage capacity and extreme compressive strength. Due to a particularly large number of dimples and a smooth back the best load distribution and perfect protection on the waterproofing achieved. In addition, a new type of overlapping system according to the push-button principle. This is easy to use and completely regardless of weather conditions. The laminated high-quality, particularly stable geotextile perfectly rounds off the range of product advantages

- This two-layer system protects the underlying waterproofing safe against mechanical damage, but also against harmful thermal stress. The optimum water drainage capacity is many times higher than required by the drainage standard DIN 4095. The dimpled membrane protects external basement walls and underground car park ceilings, terraces and green flat roofs safe from waterlogging

- The moisture gets through the geotextile into the dimple channels and is safely discharged there. The geotextile acts like a filter and prevents the nub channels from silting up. The optimal high-performance geotextile has a very high initial strength with minimum deformation under increasing service load

Installation - vertical:

- The membranes are cut diagonally to the roll to the correct length and laid lengthwise from top to bottom: The geotextile always faces outwards – towards the ground

- It is important to ensure that the sides of the individual membranes overlap while lifting the geotextile accordingly

- At corners, it is recommended to fold the membrane along the edge line prior to installation. The upper edges of the membranes must be about 15 cm above the sealing at all times

- The membrane is first attached temporarily (e. g. with wooden battens) because the drainage membrane is held by earth pressure after backfilling

- The final membrane is finally overlapped with the starting membrane over a width of at least 30 cm. The lower end rests on the circumferential drainage. The circumferential drainage is enclosed with at least 15 cm of filter-stable gravel

- After backfilling, simply cut off the membrane at the top edge of the soil

Installation - horizontal:

- The surface to be drained should have a gradient of at least 2 %

- Roll out the membrane on the sealed surface with the geotextile facing upwards. Ensure that the individual membranes overlap while lifting the geotextile accordingly

- With rising building elements, the drainage membrane should be raised at least 15 cm or to the upper edge of the filling

- If the laid membranes have to be extended, the connecting membrane is pushed under at least 20 cm from below

- With earth-covered ceilings, the laid drainage membrane can be moved directly with a wheelbarrow; with projecting ground filling of at least 20 cm, this can also be achieved with wheel loaders