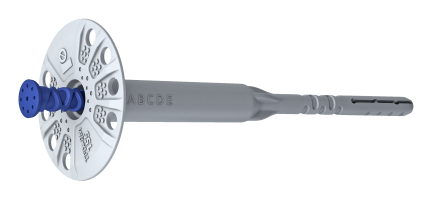

R-TFIX-8M / Hammer-in facade fixing

| SKU: | |

| EAN: | |

| Brand: | Rawlplug |

| Suitable for: | ETICS, polystyrene (EPS), mineral wool (MW), polyurethane (PU) boards |

| Type: | Hammer-in |

| Point thermal transmittance, W/K: | 0,001 |

| Min. spacing, mm: | 100 |

| Min. edge distance, mm: | 100 |

| Fixing diameter, mm: | 8 |

| Hole diameter in substrate, mm: | 8 |

| Plate diameter, mm: | 60 |

| Plate stiffness, kN/mm: | 1 |

| Plate resistance, kN: | 1,53 |

| Approvals: | ETA 17/0592; UKTA-22/6290 |

Versatile Rawlplug hammer-in facade fixing R-TFIX-8M with steel nail, recommended for ETICS

Features and benefits

- Quick and easy installation in all substrates (categories A,B,C,D,E)

- Unique sleeve compression zone for precision installations

- Reduced point thermal transmittance to 0,001W/K thanks to high steel nail overmould, which decreases facade heat losses

- Highest loads with anchoring zone reduced in length to 25 mm

- Excellent plate stiffness (1,0 kN/mm) ensures smooth elevation surface and stable insulation system

- Increased head diameter enabling centric hammer driving for improved installation comfort

- Pre-assembled components of the fixing allow you to save time

Applications

- External Thermal Insulation Composite Systems (ETICS)

- Polystyrene (EPS) boards

- Mineral wool (MW) boards

- Polyurethane (PU) boards

- Cork boards

- Light wood wool building boards

Installation guide:

- Drill a hole of required diameter and depth

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in aerated concrete block

- Clean drilled hole 3 times

- Bottom side of the plate must be flush with the ETICS

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in aerated concrete block

- Hammer the nail into the plastic sleeve until fixing is secure and flush with insulation material

- In soft insulation panels the fixing should be combined with insulation retaining plates

Video: https://youtu.be/1CJdqPJLG6Y

_MAZAIS_2017_WEB.jpg)